Web site created by Donato Borello, Amsal Karic, and Randal C. Nelson

Information Treasure Details

The project specifications required the artifact to encapsulate an "information treasure" to give it a reason for being. Our team had to answer two questions. How? and What? We will discuss the "how" first, because what we can preserve will be highly dependent on the storage modalities available to us.

Motivation

The information treasure aspect of the project was partly motivated by the observation that more and more of the information produced and used by our society is in fragile, digital form. This includes not only software, which is somewhat digital in essence, but almost all more traditional information representations, including images, text, music, photographs, and video. In digital, electronic form, this information is essentially unrecoverable without high-technological infrastructure.

Pictures, manuscripts, written music, can be interpreted by a single, educated person. With some effort, the content of vinyl records, magnetic recordings, and celluloid film could also be recovered by the efforts of a knowledgable individual with access to 19th century or even earlier technology. Not so with current digital media. Digital electronic processing is required to access the information. Making an electronic computer requires a huge technological infrastructure. No individual, regardless of the knowledge they possessed, could play the music on a CD or view the jpg pictures on an SD card with access to 19th century, or even 1940s technology.

A reasonable long term solution is for appropriately regulated, long-lived institutions to provide information-storage (and processing) services, much as banks currently provide financial services. But it would also be nice to have individual digital information artifacts that could be expected to be accessible even if picked up decades (or centuries) after their manufacture. Because no current digital medium or information standard has remained in use for more than a decade or two, such a device must be entirely self-contained. To make the problem interesting, we specified that the information be accessible with no external technological infrastructure.

Digital Dilemma

The obvious dream for an electronic information artifact would be to exploit the flexibility and information density available in current digital media. This proved unworkable for our team for several reason.

First, we simply did not have sufficient experience to design and implement an original information display system from basic computational components in the time frame of the project. Existing complete systems (e.g. game boys, tablets, etc.) did not plausibly seem modifiable to last 1000 years, though there was some discussion of trying to harden a solar calculator.

Second, there were significant questions as to whether basic components of sufficient durability even exist, and if they do how to obtain them. This was particularly true for display devices. Some of the issues we encountered are addressed in the second part of this discussion.

Third, we had a power problem. Microprocessors and displays tend to be relatively power-hungry, and the steady-state power we had available was on the order of a few tens of microwatts, with a maximum of a few milliwatts if a user wanted to cart the artifact into full sunlight. This requires very careful component selection, further limiting our options.

Non-digital options

So we were stuck using electronic functionality primarily to advertise the artifact while resorting to non-digital media to contain the information treasure.

There are a variety of information artifacts that have held up for 1000 years or more. Stone engravings are well known, though most of them would not fit in a pocket. Engravings on gold or bronze have also survived millennia, though metals, particularly gold, are likely to be repurposed by their possessors. Even pen and ink on parchment can last 1000 years if carefully cared for (e.g. not run through the wash). So we could make a durable box and fill it with a scroll of engraved stainless steel (or other modern parchment equivalent). This is rather old-school, but the idea of physically constituted graphics is certainly viable.

A slightly more appealing variation is to use modern technology to miniaturize text and other graphical material, and have the artifact provide a way of viewing the miniaturized material. This could increase considerably the amount of information that could be inscribed on a particular visible surface. So basically microfilm designed to last.

Silicon Etching Idea

Our initial idea was to use modern VLSI fabrication technology to etch text and graphics onto a piece of silicon. Silicon is extremely durable, and if protected from physical damage by a transparent window of quartz or some other hard material should be viewable indefinitely. Such a silicon record would be waterproof, resistant to most chemicals, fireproof up to about 1000C, and unaffected by light and radiation.

Modern (2012) VLSI technology can etch silicon at a resolution of approximately 20 nanometers. This is far below the approximately 1 micron resolution of a simple light microscope, so a fairly simple foundary by today's standards could produce anything we could hope to make viewable. If we used a 10 micron square character block, approximately a million characters could be placed in a square centimeter. This is the equivalent of a good-sized book, so in principle, we could store a lot of information.

There are currently companies (e.g. nano-arc right here in Rochester) that claim to offer such silicon transcription as a method to preserve valuable records. We say "claim" because when we got in touch with Nano-arc, they got a bit cagey and couldn't give us a price for a small piece of work. Seems they may be looking for big corporate contract to get their business model off the ground.

We contacted foundary services at UR and elsewhere, and discovered that the crucial step is the production of a mask. This should not be too hard at 1 micron resolution as simple optical techniques should suffice. However, foundary facilities are set up to manufacture much higher resolution, and those masks are much more expensive to produce. Ultimately, our team could not find a facility that would do a low-resolution job for us starting e.g., with images. They are set up do do one thing, and it isn't exactly what we needed. We have a feeling that with the right contacts, the job could be done without too much trouble, but we didn't find those contacts for this project.

Consumer Printing Idea

Modern consumer printers are designed to generate good-quality photographic prints, and are capable of surprisingly high resolution, advertised at 600 dpi (dots per inch) or more in black and white. Advertised specs for color printing make claims such as 2400 x 9600 dpi. It is not clear what this meeans. Examination of output images suggests that the systems do not come close to being able to print multiple lines within 1/1000 inch, which a literal interpretation would suggest.

With a 10x10 dot character block, 600 dpi should permit 3000+ characters to be printed in a square inch. We experimented with several of the laser printers available to us and found that using a fixed-width terminal typeface gave us the most legible small letters. We were able to legibly print about 1000 characters in a square inch. Smaller than that seemed to hit the practical resolution limits of the printers. Oddly enough (or perhaps not so oddly) this is approximately the smallest size that can be read without magnification, though reading is much easier with magnification.

How

Given the considerations discussed above we ultimately decided to preserve information as a microprinted image. Due to constraints on artifact size, we were limited to about 1 square inch of printing. Use of a scroll could increase the available area, but we did not think anything we could print would stand up to being repeatedly rolled back and forth over 1000 years. Engraved stainless steel foil, wound below its elastic limit might stand up, but we did not have facilities to produce it. A scroll would also require the fabrication of a robust mechanical winding system. The components would be large, and rotation slow, so this might be possible to construct.

What

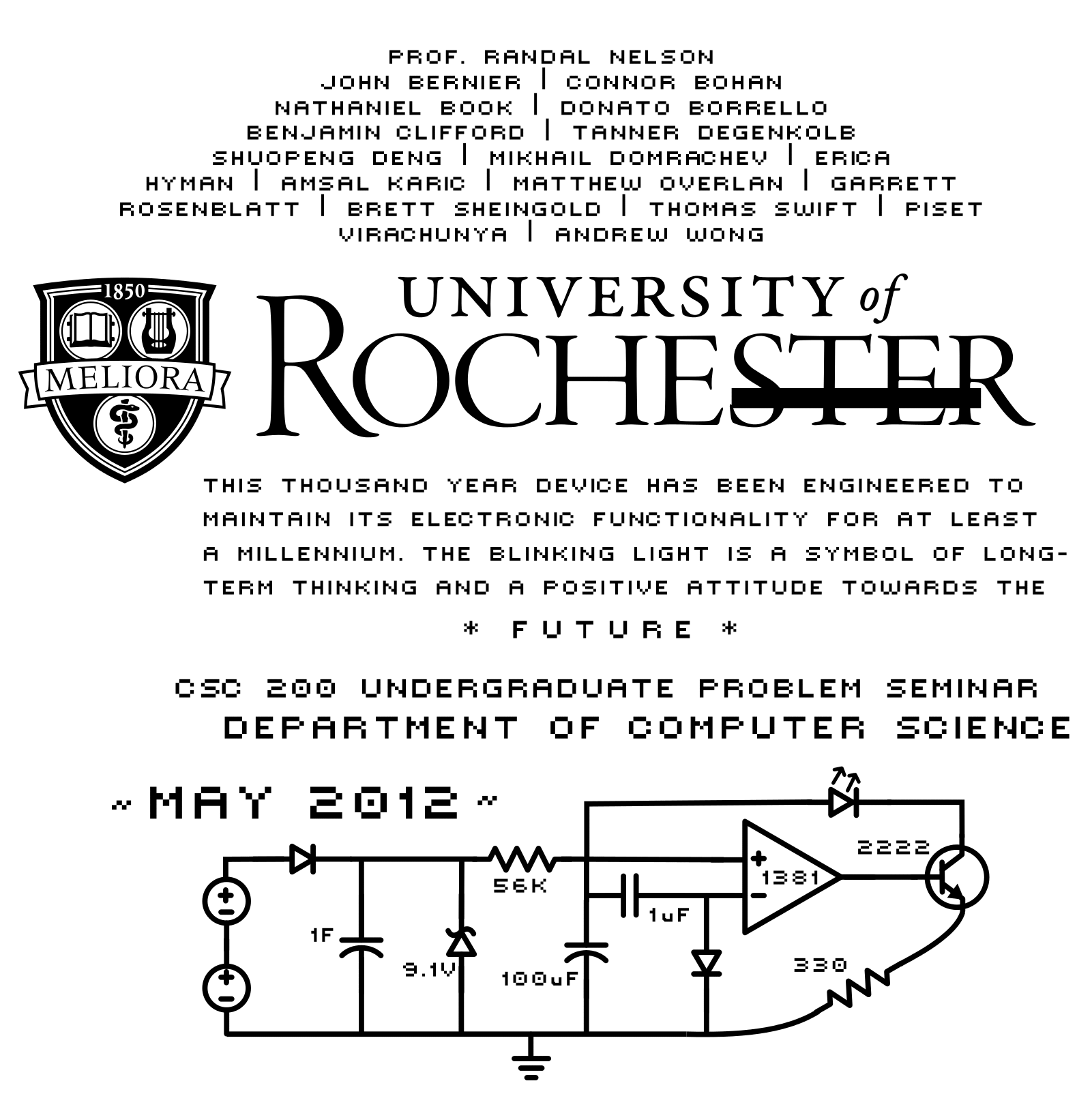

With only space for a thousand characters or so content was limited. What information is worth preserving 1000 years? Suggestions included the American declaration of independence, Newton's laws of motion, Maxwell's equations, and pi to 1000 places. Eventually we decided that the most important information to associate with the artifact was who made it, when, and why. We also included a circuit diagram of the electronics inside, as that mechanism is not obvious from direct examination.

The final image is shown below. The circuit is not quite what ended up in the artifact as it was modified slightly for better energy usage after the printing was complete. The black bar through "Rochester" is a format conversion artifact, probably due to a bug in some piece of freeware, and is not present in the original.

Fabrication

For printing, we used a laser printer rather than an inkjet. Black laser printer toners consist of inorganic pigments (usually metal oxides) mixed with a polymer base that permits the powder to be fused to the substrate. These pigments are essentially unaffected by light or air on a time scale of thousands of years. Inkjet inks often contain organic dyes that fade over a few decades. Pigment inks are available, but these seemed to offer no real advantage over laser toners for black on white printing.

For a substrate we used a synthetic, waterproof paper, specifically Graytex "Powerpaper" product #204. This is a synthetic, plastic-based material that is waterproof and tear resistant. It is specifically designed for outdoor use and for laser printing. Ordinary paper will yellow and become brittle over a period of decades due to residual acid content. Special acid free papers are more durable, and can last for centuries in protected environments, but we thought we would try a modern high-tech material. How the plastic will actually hold up over a century or more is untested, but since it is designed for durable, outdoor use we thought it might have a chance in the protected environment of the artifact.

For protection against air and light, the printed image was laminated to a piece of yellow glass, which blocks blue and UV radiation. an The laminated unit was sandwiched mechanically between a metal base plate and a viewing block. This positive-pressure arrangement provides retention of the substrate and protection of the printing even should the lamination and bonding of toner to the substrate fail. It should even protect against disintegration of the substrate as long as the mechanical sandwich is not disassembled.

The micro-printed "Information Treasure" beneath protective yellow glass.

The viewing block is provided with a magnification system, specifically, a high-quality, glass lens, flat-field jeweler's loupe, providing approximately 8X magnification. The magnifier is set so the image is in focus and of the same apparent size at any distance from the artifact (though field of view is limited to the angle subtended by the lens at that distance). Illumination is provided by ambient light admitted through 4 glass ports in the housing.

Components of the optical assembly for viewing the micro-printed image.

From left to right, top to bottom:

Base plate, Protective paper gasket, Glass laminate assembly,

Upper gasket,

Viewing block, Magnifier assembly, Outer housing viewport.

Prospects

The prospects for our small information treasure surviving 1000 years seem fairly good as long as the artifact is not subject to severe physical abuse. If the bronze casing is breached, there is some potential for the internal metal supports, which are made of aluminum, to suffer corrosion damage in damp environments. Although the lenses of the optical assembly are made of optical glass and should retain their transparency for centuries, the manufactured retaining housing is acrylic plastic. Although it is carefully not subject to mechanical stress, there is some possibility that eventual degradation of this plastic inside the sealed bronze enclosure could result in mechanical failure of the magnifier. There is also a possibility that outgassing from slowly degrading plastic could produce deposits that cloud the glass lens surfaces.

Problems and Prospects for a Digital Information Treasure

As mentioned above, we did not find a fully digital information storage and access technology that would plausibly be operational after 1000 years. We did do considerable research on the issue. We discuss some of the issues we encountered with respect to durable electronic information systems below.

Information Processing Requirement

All current digital information standards have one issue in common: namely, that information is reduced to serially stored and often complexly encoded bits, and needs a sophisticated microprocessor to render it into human-accessible form. This is usually done using general-purpose processors, hard coded for the specific device, though custom circuits are occasionally employed.

Robust microprocessors and persistent memory technologies (ROM and PROM) have been fielded, for instance the radiation-hardened systems in NASA spacecraft, (and presumably military hardware). Some of these components might be adapted to long-lived artifacts. Hardened processors however, tend to use larger feature sizes and hence be comparatively power-hungry, and not a good match for our very limited power budget. The memory in which the programs that implement the system functionality are stored must be extremely robust, as a single bit error anywhere in a program can be catastrophic. This is a fundamental weakness of current computational architectures. NASA systems sometimes completely duplicate or triplicate systems to detect errors in execution or stored programs. The usual recourse on error detection is to rerun or vote, and then ask for outside help to fix things up before faults accumulate. Unfortunately, outside help is not an option for our application.

In any case, we did not locate a source for hardened components, though additional effort might pay off here. We also did not have the expertise to design and build a custom system from components in the time frame of the project.

Presentation Technologies

Information recovered and decoded by a microprocessor needs to be rendered into some human-accessible form. The best developed presentation modalities are visual and audio. Current tactile displays are primitive, smell and taste practically non-existent (and of questionable utility). Direct brain stimulation is largely a theoretical possibility, and a very invasive and risky one with current ideas.

Graphical Presentation

The most common presentation mechanism is graphical display, either high or low resolution. Graphic display technologies include CRTs, LCDs, Plasma displays, and LEDs. All high resolution displays require complex driver circuitry. Advantages and disadvantages of some display technologies with respect to our application are listed below.

- CRTs: Bulky, power hungry, need high voltages and complex analog circuits, have electron emission filaments that eventually burn out, and high-vacuum tubes that leak and fail within few decades. Not a good fit for our pocket device.

- LCDs: Tend to be fragile, though more robust ones could probably be made. The possibility of low power, low-voltage operation using ambeint light is a plus. The long-term stability of the organic "liquid crystal" molecules and chiral dopants is untested, but they are probably susceptible to radiation damage and slow thermal degradation. The transparent conductors driving high-res displays are, by their nature, a bit delicate. Given the observed failure rate of even low-res LCD displays in current devices, they seem a bit iffy for 1000 years.

- Plasma displays: Designed to be robust. The basic display element is a glass plate with lots of tiny holes through which an electric discharge causes a low-pressure gas to glow. They are relatively power hungry. Over the long term, the low-pressure gas discharge environment can leak and become contaminated. Current panels would probably not last 1000 years.

- LEDs: Power hungry compared to ambient-light LCDs. Current high-resolution displays utilize organic light emitting diodes (OLEDs). They appear to be robust, but have only been around a few years, and the long-term stability of the OLED materials is unknown. As complex organics, they may be susceptible to radiation damage and slow chemical/thermal degradation. Low-resolution LED displays using discrete, conventional LED materials have been around for four decades. Some of the original displays are still operational. A low-res alpha-numeric display composed of LED elements might stand up, if well protected.

Audio Presentation

Some information can be delivered via audio. Music is intrisically acoustic, and text can be read. Audio transducers are considerably simpler than graphic displays. Conventional speakers will last several decades easily, though many contain elasomeric elements that will eventually deteriorate. Most conventional speakers are also somewhat fragile. There are however, small, piezoelectric speakers commercially available where the crystal element directly drives a stainless steel diaphram. If protected from severe mechanical abuse, such a device has the potential to remain operational for centuries.

Our original design included an audio transducer, and we obtained some of these elements for testing. Ultimately the power requirements were higher than we could supply without redesigning our circuitry for intermittant use, and the teams were out of time. However, piezoelectric audio seems a definite possibility for a durable presentation method. The main concern with the units we obtained is the possibility that elasomeric adhesives were used in sealing the container and attaching the crystal to the stainless steel diaphram. We did not tear one apart to find out.

Digital Information Storage

A wide variety of technologies are currently used to store digital information (relatively) long-term for computer access. Some of the most widely used still have a mechanical component. Current motors and other precision mechanical components simply do not have sufficient durability for our project. Small motors tend to last a couple of decades at the outside, and most fail sooner than that. Solid state storage technologies are more promising, but many of these have significant issues as well. An information treasure requires durability and stability, but significantly, does not require that the storage be re-writeable. Pros and cons of some common technologies are listed below.

- Tapes: Need motors and other complex mechanical parts. Plastic base subject to degradation. Magnetic coating flakes off due to mechanical stresses and failure of adhesion. Not suitable.

- Magnetic disks: Need motors and high precision servo mechanisms. Must remain completely sealed from outside environment. Not suitable.

- CDs and DVDs: Require motors and complex servos. Plastic substrate will eventually degrade on exposure to air and light. Scratches, dirt, and microcracks on the disk surface destroy accessibility of stored data. Not suitable.

- Magnetic "Core": The original computer "core" memory consisted of small magnetic rings strung on wire grids. Somewhat surprisingly, this might be a workable technology for our application, as the magnetic hysteresis is stable over very long time scales, the elements are large, and the materials are stable. Problems include low information density, temperature sensitivity, and high cost. Unfortunately, magnetic core memory has not been manufactured since the 1970s, and is neither commercially available, nor buildable with easily available laboratory facilities.

- Mask ROM: The conventional form of read-only memory is based on diode patterns fabricated directly into an integrated circuit. This would hold up as well as any other integrated circuit, and potentially has the required durability for a 1000-year artifact, especially if well protected. Disadvantages include high overhead cost, as a mask must be produced and custom chips fabricated. This is particularly prohibitive for a one-off system.

- PROM: One-time programmable read-only memory uses technology that allows links in a general circuit to be selectively destroyed by applying a high programming voltage. The result has most of the properties of regular mask ROM, but has much lower cost for one-off systems. This might also be suitable for a 1000-year artifact.

- EPROM: Eraseable-programmable read-only memory makes use of floating-gate transistors, where data is stored by forcing electrons through an insulating layer onto an isolated metal control gate. Exposure to UV light produces ionization in the insulator allowing the charge to leak off and the memory to be erased. Data storage in floating gate arrays is somewhat more fragile than conventional mask ROM. The charge can slowly bleed off over time, and the process is accelerated by increased temperature and certain forms of radiation. Because the insulator accumulates damage each time electrons are forced through, the number of rewrites is typically limited, though this is not an issue for our application. Commercially available chips have a design lifetime on the order of 20 years, which is rather marginal for a 1000-year artifact.

- EEPROM/Flash: This is erasable-programmable read-only memory that can be erased electrically rather than be exposure to UV light. Data storage employs the same floating-gate mechanism as UV-EPROM. Flash memory is a fast, durable, and very dense version of EEPROM that has become cheap and widely used in the last decade. The same charge leakage concerns exist for Flash as other EEPROM. In addition, the data density of current technology has reached the point where the difference between an "on and "off" gate is on the order of a few dozen electrons. This can easily be deposited by ionizing radiation from cosmic rays and possibly by ordinary radioactivity as well. The stability of Flash over 1000 years is extremely questionable, and it is probably unsuitable for our project.

- Resistive Memory Technologies: A variety of new, non-volatile, solid-state data-storage technologies are in various stages of commercial development. These include Magneto-resitive memory (MRAM), Phase-change memory (PRAM), and Resistive dielectric memory (ReRAM). In these technologies, data is stored by changing the resistance of a memory cell in various ways. In MRAM this is accomplished by magnetizing a small feromagnetic element; in PRAM, by melting and modifying the phase of a memory cell by controlling the cooling rate; in ReRAM by the formation of conduction paths in a dielectric. These technologies do not suffer the charge-leakage problems of floating-gate methods, and have potential durabilities on the order of centuries. Certainly something to watch for the future.

CSC 200 Spring 2012 Project

The goal of the class project was to design and build an electronic artifact capable of operating continuously for a span of 1000 years.

The constraints include:

Compactness--Capable of fitting into a pocket or even being wearable.

Attractiveness--Having an attractive final look.

Durability--Capable of tolerating anything from an accidental drop on the sidewalk to a run through a washing machine.

Autonomy--Having a self-sustained power system and not needing any human intervention through its run of a millennium.

Treasure--Having an informational treasure which can be viewed in an easy way.

Price--The materials and components making up the artifact need to cost less than $1000 in total. (This does not include the value of student labor.)