Web site created by Donato Borello, Amsal Karic, and Randal C. Nelson

Electronics Details

The electronics component constituted the high-tech aspect of the project. Durable physical artifacts have been constructed throughout history. Part of the motivation for this project was the observation of the temporary nature of current technology. Computational hardware is outdated in five years, and devices generally are not constructed to last much longer than this. Not only the devices, but the entire high-tech infrastructure that supports them, hardware, software, communications standards, interface standards, storage media, etc. etc. changes on the same timescale. Any computational device more than ten years old, even if it still runs as an individual unit, is of limited utility because it cannot connect to the rest of the world any more.

Despite all this, solid state electronic technology is potentially extremely durable. Transistor radios from the dawn of the solid state era often still work. The most common causes of failure are damage to the physical housing, corrosion of connections (most frequently due to battery leakage), and component breakage due to shock, impact, or mechanical cycling. The only electronic components that commonly fail electrically are electrolytic capacitors. Computer chips do fail, most often due to overheating, but sometimes due to failure in solid state devices. When one considers that a modern computer chip contains several billion (unbelievably small) transisters and other components, the fact that a motherboard will, more often than not, run for five years without trouble is remarkable testimony to the robustness of solid state circuitry.

Functionality

Unfortunately, although solid state electronics are intrinsically robust and durable themselves, the interface hardware connecting them to users and the world to make useful devices is not. Keys and buttons are moving mechanisms with exposed contacts that wear out, corrode, and fail. Graphic displays tend to be physically fragile, and it is unclear how stable the complex organics in LCD and OLED displays are under exposure to light, thermal cycling, contact with substrates, and simple thermal aging, even on the scale of decades, let alone centuries. Certainly display failures are common in modern devices.

There are alternatives. Switches can be replaced with non-moving optical, conductive, or capacitive sensors. These can be made physically robust, and embedded in a durable housing. Displays based on inorganic LEDs can be made strong and durable, as can plasma displays, though it is unclear if the gas pressures needed for plasma display operation could be retained for centuries. Physically robust display elements are made for the military, and some of these might be made to operate over a centuries timescale, especially if not "on" continuously. Driving a graphic display requires at least a modestly sophisticated microprocessor, probably specially hardened, and if not some pre-fabricated system, robust components for program and data storage as well. This seemed a bit beyond the capabilities of our team to put together in a semester.

A possibly doable project along the pre-fab system lines might be to put together an "armored" solar power calculator, stealing the CPU, and replacing the buttons with non-contact switches, the power supply with a more robust system, possibly replacing the display with something tougher, and protecting the whole with a durable housing.

Our initial design idea was to construct an electronic "musical instrument" with continous control via one or more non-contact optical sensors that could be covered to varying degrees. For production of the sound, we planned to use piezo-electric speaker protected by a robust grille, possibly removable for cleaning. Small piezo speakers constructed of ceramic and stainlesss steel are available at modest cost, and if protected from physical damage, might function for centuries. The overall effect would be something like a theremin. The electronics team constructed a working prototype using a IC-555 timing chip, cadmium sulphide photoresistors, and a handful of other discrete components.

This initial design was based on the published rating of 6.7V and 31mA for the solar cells we planned to use as a power source. These figures are based on a standard model of direct sunlight. Part of the requirement was that the artifact be able to operate in ambient (bright office level) lighting. We discovered that under these conditions our cells generated only 4.8V open circuit, and about 50uA short circuit. The available power was about three orders of magnitude less than the full sun rating would suggest. Since our IC chips consumed about 1mA even in the quiescent state, this was clearly not going to work. Our initial attempts to design a switched system that could be turned on when sufficient energy had accumulated drew enough current in the off state to prevent any energy accumulation. By the time we devised a switch that did not draw more than a few uA when open, it was rather late in the game, and we resorted to more basic functionality.

Minimal functionality in an electronic circuit would be some sort of "I'm alive" indication, e.g. a beep or flash. A continuously beeping artifact would likely be quickly silenced by annoyed humans, so we opted for a circuit that would blink an LED when powered. It turns out that a current averaging 5uA at 5V is sufficient to produce a LED flash once a second that is clearly perceptible in daylight. This is within the range of the power we have available in ambient light, even accounting for periods of overnight darkness, (assuming the ability to store power overnight).

Electronic Design

We need a periodic switching circuit that does not drain more power than the LED. We built a few flasher circuits using low-power bipolar junction transistors and simple designs the electronics team found on the internet. These all drew too much current in one way or another. Some kept the LED on too long. Some drew power through the bias resistors. Probably a MOSFET or cascaded switch design could be used to reduce quiescent drain, but then we discovered the Panasonic MN1380 series voltage detection IC and similar chips from other manufacturers. These integrated circuits are designed to detect abnormal power supply conditions in electronic devices (e.g. low battery), and trigger appropriate action. Because they are often used in battery-powered devices, they must draw minimal current (generally 1 uA or less) to avoid draining the battery themselves. The chips typically have an output that goes high (or low) when the input voltage passes a threshold. They also have built-in hysteresis (typically about .2V) to prevent oscillation around the transition point. A very low average power flashing circuit can be built from one of these chips, one transistor (switch), one capacitor (dual purpose energy storage and timing), a couple of resistors and an LED. Pretty minimal. (Of course the chip itself contains several dozen transitors and other elements, but from our point of view it is a simple functional unit)

The inspiration for this approach came from solar engine circuits used by light-powered robot hobbyists to accumulate power from a small solar cell into a capacitor, and discharge it through a motor when sufficient energy is stored rotate the motor a bit. These circuits tend to use some sort of latching mechanism to keep the switch closed until most of the capacitor energy has been used. To flash an LED, the hysteresis built into the chip is sufficient (and in fact, leads to very efficent energy use as the source voltage approaches the threshold) so the circuit can be simplified.

The important technical characteristics of these chips include the threshold voltage (available chips range from approximately 2.0V to 5.0V) and the output mode. Output modes include CMOS and inverted CMOS, and N-channel drain. The CMOS outputs a voltage near the input when the input is above the threshold and 0 otherwise. Inverted CMOS outputs the input voltage it is below the threshold, and zero when the threshold is exceeded. N-channel drain essentially grounds output when the input is below the threshold, and must be externally powered to produce an output voltage. This property made the N-channel devices unsuitable for our application as the external power circuit draw too much current in the grounded "off" state.

As of 2012, the original Panasonic MN1380-1381 line was effectively discontinued, and hard to obtain. We used a similar chip from Microchip Technology's TC54 line, specifically the TC54-VC3002EZB-ND. The is a CMOS output chip with a 3.0 V threshold and through-hole, 3-pin packaging.

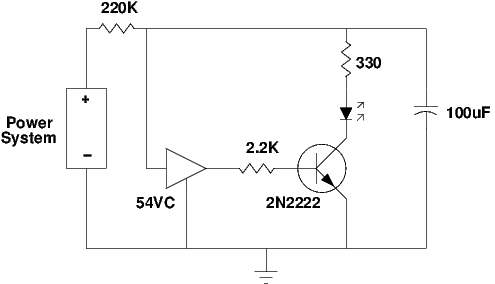

The circuit used is shown below. Note that this is not exactly the circuit shown on the graphic contained in the artifact. The original circuit, once assembled and attached to the solar power system proved to draw too much current for the ultracapacitor to power it overnight. The circuit below is more energy efficient (and simpler) and runs overnight easily.

The circuit works by charging up the 100uF tantalum capacitor through the 220K resistor. When the voltage reaches 3.0V, the output of the TC54 goes high, turning on the 2222 transistor, which discharges the capacitor through the LED until the voltage drops below the hysteresis differential (about 2.8V).The TC54 then resets to low, the transitor turns off, and the process repeats. The 330 and 2.2K resistors protect the LED and the transitor from high currents. In this particular configuration, the flash lasts about 1/20 of a second. The rate depends on the voltage from the power system, but in north-light window conditions averages a bit over 1 flash per second.

The run time can be estimated by looking at the RC time constant of the overall circuit. In this case, C is the one farad ultracap in the power system, and R is the 220K charging resistor. The time constant is thus 220,000 seconds, or about 2.5 days. This should get us overnight easily. As it turns out, the internal discharge rate on the ultracap is of the same order or larger, so there is no advantage to reducing the power further.

Assembly

The components were assembled on a piece of standard 5-in-line printed circuit board cut to size, together with two small components of the power circuit (a 9.1 V zener diode to protect the ultracap, and a schottky diode to prevent the cap from discharging backwards through the panel in low-light conditions). A nicely aligned version can be put together with only one internal jumper. Leads were attached for connection of the solar panel, the ultracapacitor, and the LED beacon. All connections were made with Sn96.5 Ag3.0 Cu0.5 silver-bearing solder. Leads were solid wire, and connections to leaded external components were soldered and covered with shrink tubing to prevent any accidental shorts. The solder connections on the bottom of the circuit board were protected against shorts and damage by a piece of 1/8" polycarbonate plastic attached with epoxy resin. The circuit board, along with all the other electronic components, was embedded in paraffin wax on final assembly as described in the housing section.

Prospects

So will this circuit run for 1000 years? We don't know. Solid state elements, resistors, and tantalum capacitors, when protected from the environment and high temperatures are all extremely durable. Our maximum currents are all well below the specs of the devices, and occur only briefly, so ohmic heating should not be a problem. Modern high-intensity white LEDs are rated as high as 100,000 hours (about 11 years of continuous operation). 1/20 second every second, it would take over 200 years to accumulate that much burn time. We have a low intensity red LED, which is probably longer lived than high intensity white ones, so based on that figure we have a shot. There may, of course, be age-related failure modes no-one knows about. The TC54 is an LSI circuit running at extremely low power. Some such chips have been running ever since they were developed, so again, nobody knows.

The solar cells and ultracapacitor in the power system are probably more vulnerable than the electronic components described here. Some of their issues are discussed in the power system details section.

In the end, only time will tell.

CSC 200 Spring 2012 Project

The goal of the class project was to design and build an electronic artifact capable of operating continuously for a span of 1000 years.

The constraints include:

Compactness--Capable of fitting into a pocket or even being wearable.

Attractiveness--Having an attractive final look.

Durability--Capable of tolerating anything from an accidental drop on the sidewalk to a run through a washing machine.

Autonomy--Having a self-sustained power system and not needing any human intervention through its run of a millennium.

Treasure--Having an informational treasure which can be viewed in an easy way.

Price--The materials and components making up the artifact need to cost less than $1000 in total. (This does not include the value of student labor.)